N&S options for touch screen fitting

Strip Bonding

This is where strips of double sided gasket are placed on the bezel of the display forming a frame. The touch screen is then aligned in the correct position on the display to form the final assembly ensuring an easy to integrate product for the customer.

Depending on the application and budget, we can either use roll gasket which is applied in straight strips with a join on the corners. Alternative for the high end requirement, we are able to die-cut a double sided sheet gasket which allows for a seam free border.

Other Bonding

We have also gained a wealth of experience in glass and filters, we have bonded both ITO and EMC mesh filter glass.

We are able to recommend and give direction on type of glass from Gorilla (Xensation) glass, different thickness of glass, toughening through thermal or chemical treatment, surface treatments (AG / AR), and printing (organic / ceramic)

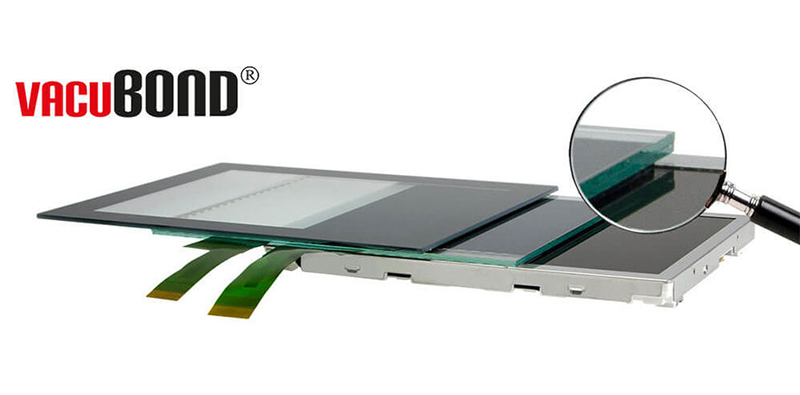

Optical Bonding

Optical Bonding is the process of applying a silicone layer between the TFT LCD and the touch glass eliminating the void, this enhances daylight readability, increases ruggedness and avoids ‘fogging’.

Unlike the majority of display distributors, N&S Ltd have set up an optical bonding clean room facility in our Munich headquarters and our USA facility.

Having these facilities allows us to control the quality, reduce expensive freight cost from the Far East and allows for rapid prototyping.

The optical bonding facility will also undertake projects where either the display or touch (or both) is free issued.